The metal sheet works be well fulfilled by laser cutting, CNC punching machine, traditional punching, cnc bending machine and welding.

We have two laser cutting machines, one CNC punch, 6 traditional punches and 4 CNC bending machines.We also specializing in MIG welding, TIG welding. Meanwhile, We have a powder coating line for surface treatment.

Casting process refers to the process that metal is melted into a liquid that meets certain requirements and poured into the mold. After cooling, solidification and cleaning, castings (parts or blanks) with predetermined shape, size and performance are obtained. It is the basic technology of modern machinery manufacturing industry.

Our contracted foundry has two casting methods: sand casting and investment casting. Can produce iron castings (gray iron, ductile iron), steel castings (carbon steel, alloy steel, stainless steel).

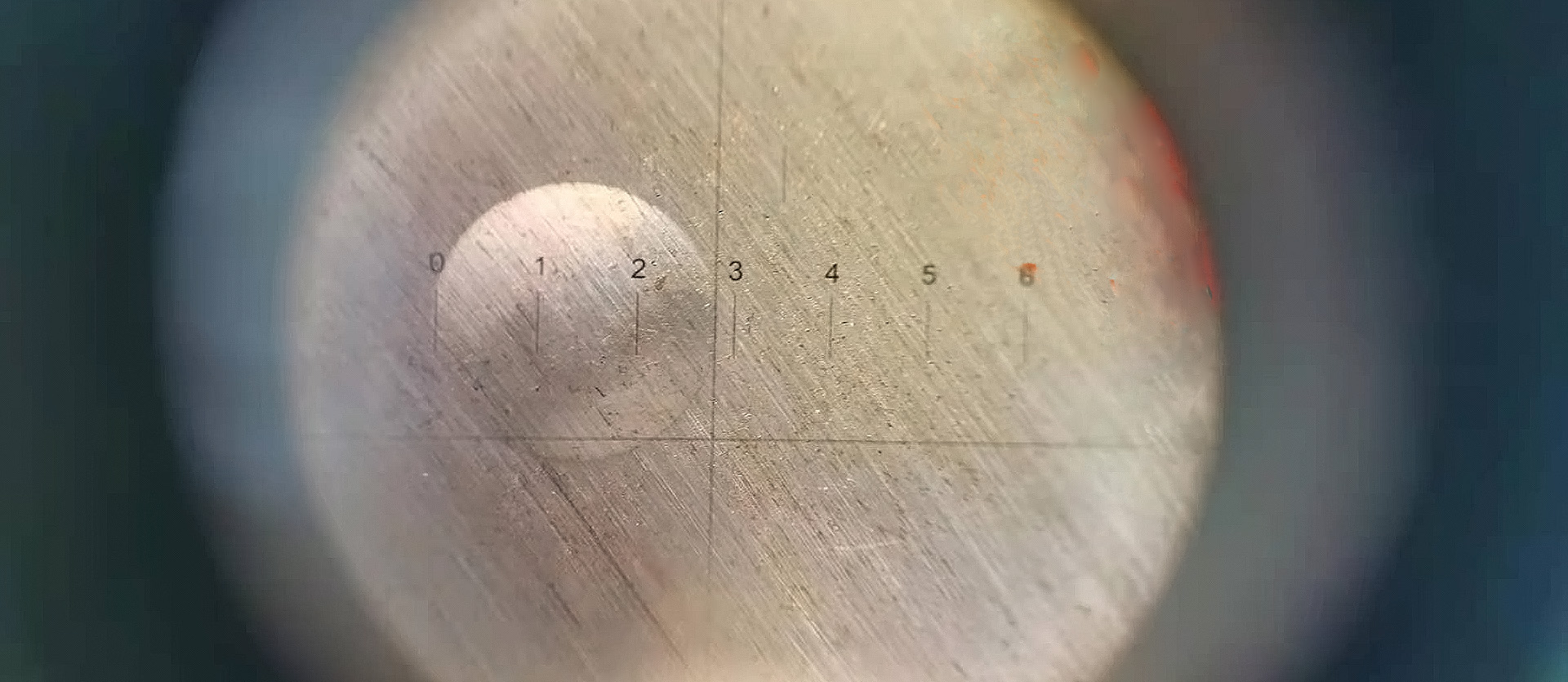

It refers to the whole process of making the shape, size, relative position and properties of the blank become qualified parts according to the drawing and size of the drawing by using the traditional machining method.Our company has CNC Millings, CNC lathes, CNC drilling and tapping machines and other high-precision machining machines.

The CNC machining division, has the chances to support fast prototypes and low-medium series production. Thanks to the 3+1 axes machineries, with single or double pallet, we can approach several kinds of raw material, such as steel, aluminum, plastic. All the CNC machineries are supported by an innovative CAD-CAM system in order to optimize and speed up all the process.